Combi boilers are clever little beasts - compact, efficient, and perfectly capable of heating your home and hot water without bulky tanks cluttering up your airing cupboard.

But if your valves aren’t in the right position, you can wave goodbye to peak performance.

You might even face leaks, cold radiators, or a winter morning shower that makes you wish you’d stayed in bed.

Combi boilers are now more sophisticated than ever, but they still rely on correct valve positioning.

In this guide, we will walk you through what the valves do, where to find them, how to keep them set correctly, and when to step back and let a Gas Safe engineer take over.

We’ll also cover installation basics, compatibility, and the financial side of owning a combi, so you have the full picture.

Let’s dive in…

🔑 Key Takeaways:

Correct valve positions prevent leaks, pressure spikes, and costly breakdowns.

Filling loop valves must be closed during normal use – leaving them open is a common and expensive mistake.

Isolation valves are for maintenance or emergencies only, not day-to-day tinkering.

A dripping pressure relief valve (PRV) means trouble – usually overpressure or a faulty expansion vessel.

Diverter valves switch automatically between heating and hot water; if yours sticks, expect lukewarm taps or chilly rads.

Get a new quote (finance available including 0% APR).

Understanding Combi Boilers

A combi boiler - short for combination boiler - is the heating hero in millions of UK homes.

Unlike old-school setups with a cold water tank in the loft and a hot water cylinder in the airing cupboard, a combi pulls straight from the mains and heats it instantly.

The result?

No waiting around for a tank to reheat.

No bulky tanks stealing cupboard or loft space.

Less heat loss, meaning better efficiency.

In the past five years, combis have had a serious glow-up: beefier heat exchangers, brainier controls, and slicker modulation mean they’re more efficient than ever.

But here’s the twist - all that wizardry still depends on the humble valves doing their job.

Get those wrong, and you’ll swap your toasty showers for tepid trickles and surprise repair bills.

The Main Valves on a Combi Boiler

Your combi has a handful of valves - some you can turn yourself, others you should leave well alone - all working together to keep heating and hot water flowing without drama.

Get to know them, and you’ll be miles ahead when it comes to troubleshooting or talking to an engineer.

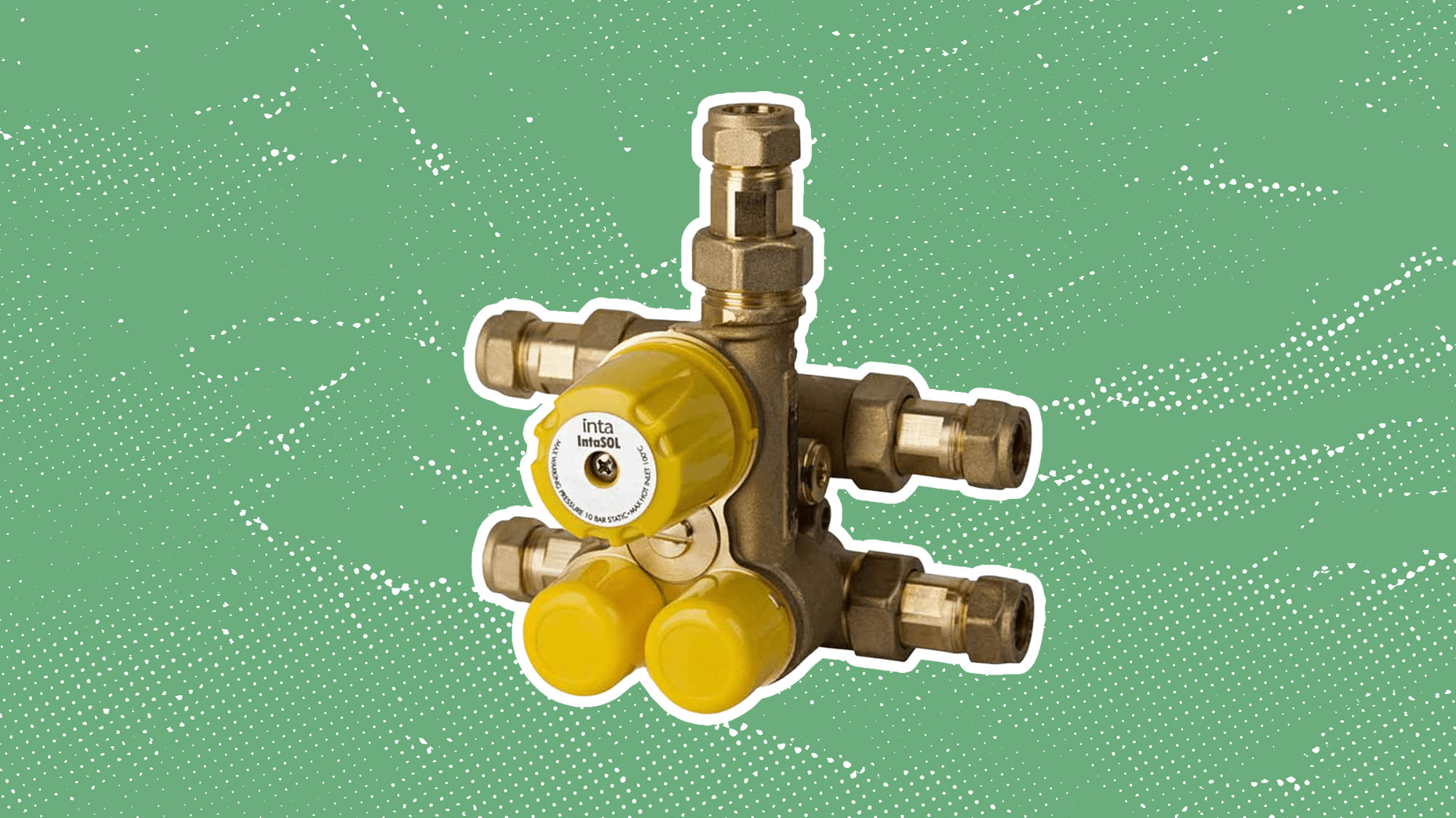

1. Filling Loop Valves

These let you top up the boiler’s water pressure when it dips below the safe range (usually 1–1.5 bar when cold).

Most combis have a braided metal hose linking the mains cold feed to the heating circuit, with two little taps - one on each end.

Open both to let water in, close them firmly afterwards. Rookie mistake: leaving them open, which will send your pressure rocketing and trigger the PRV.

2. Flow and Return Valves

Tucked under the boiler on the central heating pipes, these regulate the movement of hot water out to your radiators (flow) and back to the boiler (return).

Close them to isolate the heating circuit for maintenance - just remember that doing so will stop your radiators from heating until they’re re-opened.

3. Isolation Valves

Usually found on the gas inlet, cold water inlet, and sometimes the hot water outlet. They’re the “off switches” for specific parts of your boiler.

Use them in an emergency (like a leak) or during servicing, but make sure you know which is which before turning anything.

4. Pressure Relief Valve (PRV)

Your boiler’s pressure safety net. If the system creeps over roughly 3 bar, this valve automatically opens to dump excess water via a pipe to the outside.

If it’s dripping constantly, something’s wrong - often a sign of overpressure or a failing expansion vessel - and you’ll need an engineer.

Image showing a standard filling loop / Heatable

5. Diverter Valve

The behind-the-scenes traffic cop of your combi. It decides whether heated water goes to your taps or your radiators, depending on demand.

It’s motorised and not something you can adjust yourself, but if it fails, you’ll usually get either heating without hot water, hot water without heating, or both working badly.

Image showing a standard diverter valve / Heatable

Where You’ll Find Them

Most of your combi’s valves live either under the boiler’s outer casing or on the exposed pipework directly beneath it - neat, tidy, and (mostly) out of sight.

The pressure relief valve (PRV) is usually mounted on the side or underside of the boiler, with a small copper pipe running through the wall to discharge outside.

Spot a constant drip from that pipe? Time to call in a pro.

The filling loop is typically positioned for easy reach, often front-and-centre under the boiler. That’s so you can top up the pressure without dismantling half your kitchen.

Other valves - like the flow, return, and isolation valves - are usually grouped with the rest of the connections underneath, each serving its own specific role in keeping the system humming along.

Normal Operation Valve Positions

When your combi is running happily, all its valves should be set just so. Think of it as the boiler’s “resting face” - calm, ready, and in balance:

Filling loop valves – Both should be closed, with their handles at right angles to the flexible hose. These only open when you’re topping up pressure (usually to 1–1.5 bar when cold). Leaving them open is one of the fastest ways to overpressurise your system and trigger the PRV.

Flow and return valves – Fully open, with handles lined up neatly with the pipes. This keeps hot water flowing out to your radiators and returning for reheating. Closing these will shut down your central heating circuit.

Gas and cold water isolation valves – Both should be open so the boiler gets the steady supply of fuel and fresh water it needs. Close them only for maintenance or in an emergency.

Pressure relief valve (PRV) – Shut tight in normal use. This little safety hero should only open automatically if the system pressure climbs too high (around 3 bar). If you see it dripping constantly, something’s off.

Diverter valve – Fully automatic and hidden inside the boiler. It decides whether to send heat to your radiators or your hot taps, depending on demand. No manual fiddling required - and best not attempted.

💡 Top tip: Once your system is working perfectly, take a quick photo of all the valve positions. If anything changes after a repair or pressure top-up, you’ll have a visual guide to get things back to normal.

Adjusting Boiler Pressure Safely

If your pressure gauge has dipped below 1 bar, it’s time for a quick top-up:

Switch off the boiler and give it a few minutes to cool - safety first.

Find the filling loop (that braided metal hose with two little taps).

Open both valves slowly, keeping an eye on the gauge. You’re aiming for 1–1.5 bar when the system is cold.

Close the valves firmly - no half turns or drips.

Check for leaks and, if needed, bleed your radiators to release trapped air.

If the gauge creeps above 2.5 bar when the system’s cold, chances are you’ve accidentally left the filling loop open.

If it’s shut tight and the pressure still rises, you could be looking at an expansion vessel issue - which means it’s time to call in a Gas Safe engineer.

Isolation for Maintenance or Emergencies

Isolation valves let you shut down sections of your system.

The sequence matters:

Gas off first - lever at right angles to the pipe.

Then close the water and heating valves.

This order helps prevent overheating or damage if the boiler fires unexpectedly.

In a gas emergency:

Isolate immediately

Evacuate the building

Call Gas Safe on 0800 111 999

Common Mistakes to Avoid

Leaving the filling loop open - This floods the system with mains water, spiking pressure until the PRV vents constantly.

Forcing stiff valves - Snapping a valve handle can mean replacing the whole valve.

Wrong shut-off order - Closing water before gas risks overheating.

Ignoring a dripping PRV - This is a warning sign, not background noise.

Troubleshooting Valve-Related Issues

Valves might be small, but when they go wrong, they can cause big headaches. Here’s how to spot - and sometimes fix - the usual suspects:

Persistent low pressure – First stop - check the pressure gauge. If it keeps dipping, inspect all visible pipework for leaks, including the PRV discharge pipe outside (small copper pipe pointing down). If that’s dripping when the system’s cold, you may have a faulty PRV or expansion vessel.

Heating works, but no hot water – This often points to a stuck diverter valve. It’s directing heat to your radiators but refusing to send it to the taps. This is an internal fix, so you’ll need an engineer.

Radiators are warm, but taps are only lukewarm – Again, the diverter valve is the likely culprit, not fully switching between heating and hot water.

Constant dripping outside – If water is constantly flowing from the PRV pipe, your system is regularly overpressurising. Check that the filling loop valves are shut tight. If they are, the expansion vessel might need repressurising or replacing.

💡 Top tip: If in doubt, take a clear photo or video of the problem area and send it to your heating engineer before they visit. It can save them time - and you money.

Get a Quote for a New Boiler Today

If you’re aiming to get the best deal on a new boiler, consider getting your boiler installation with us. Here’s why:

Gas Safe installation within 24 hours.

Thousands of satisfied customers with an average score of 4.9 on Trustpilot, surpassing the market leader.

Which? Trusted Trader: Heatable is proudly recognised as a Which? Trusted Trader.

Price match guarantee: We will match any like-for-like cheaper quote.

Flexible payment options, including interest-free finance.

Up to 12-year guarantee on selected boilers.

Fixed price guarantee: No hidden costs.

Save your quote and decide later.

Get an instant fixed price on a new boiler, here.

To learn more about the best combi boilers and more, visit our advice section, check out our YouTube channel, or read customer testimonials here.

Heat Happy.